We are a global operator of essential infrastructure

Our suppliers are a key element of our activity, as well as the supply of equipment, materials, services, and works that we receive from them.

Supplier Qualification

If you are interested in becoming a supplier for Redeia, you must register on the Procurement Portal, a space created so that any company can learn about the supplies acquired by the company and the minimum requirements to be met in each case. You can access and easily view the company’s supply tree, published on the main page of the Procurement Portal. This space also allows companies interested in becoming a supplier for Redeia to register and start the qualification process.

The minimum requirements to be met are at the supplier level (business, financial, legal, technical, integrity, and sustainability) and are initially verified during the registration and qualification process and subsequently on a continuous basis during supplier monitoring.

For those supplies that, due to their nature, require compliance with certain minimum requirements, a “supplier profile” is created, which must be met in order to obtain qualification.

What action would you like to perform?

Bidding process

Subcontracting process

Request activity certificate

Redeia, in its commitment to transfer its qualification requirements to the second level (tier 2), requires subcontractors performing highly relevant and critical activities to comply with the same requirements demanded of awarded suppliers.

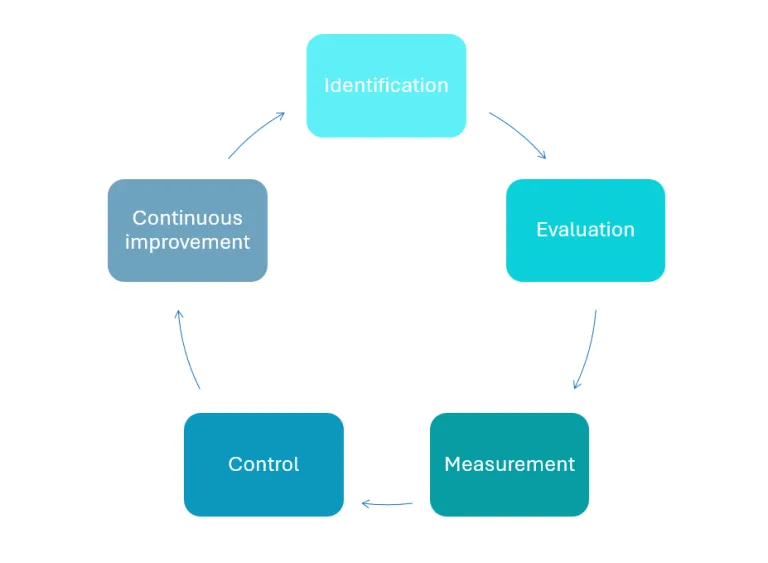

Redeia has a comprehensive supplier risk management model designed to identify, assess, monitor, and control risks associated with managing Redeia’s suppliers, in order to act on their mitigation and provide valuable information for decision-making during processes and stages related to the supply chain: qualification, bidding (supplier selection – award), and continuous monitoring (supplier follow-up).

This supplier risk management ensures operational continuity, sustainability, and regulatory compliance by covering and monitoring the following areas:

Possibility that a supplier does not comply with its obligations with the Administration (payments to Social Security and the Tax Agency)

Possibility that a supplier generates negative impacts on its performance due to deficiencies in its management systems for quality, enviroment, safety of information, business continuity, or prevention of occupational risks.

Compliance: possibility that a supplier incurs legal, regulatory, or ethical breaches that violate the principles of integrity, human rights, transparency, and sustainability promoted by the company.

ESG: these are risks derived from enviromental (E), social (S) and governance (G) factors that a supplier must manage.

Security: possibility that a supplier suffers security incidents that compromise the confidentiality, integrity or availability of information and the technological systems that support it.

Possibility that a supplier experiences economic difficulties that may affect its stability and business continuity.

Possibility that a supplier or the factories from which it sources its equipment/materials are located in countries where poor practices may occur in the areas of integrity, human rights, geopolitical factors, or that are subject to international sanctions, with restrictions on commercial operation or subject to economic sanctions.

The model is supported by a global 360 management tool (include link), fed by external sources and by the information provided by suppliers when responding to questions in the different indicated areas.

Risk in the different areas is assessed quantitatively, qualitatively, and through the parameterization of possible alerts and notifications.

Based on the established risk thresholds, a compliance score is generated for the different areas.

Additionally, the tool allows:

Managing and analyzing incidents related to performance during the execution of work in collaboration with different areas of the company responsible for contracts.

Identifying improvement actions and defining action plans to resolve incidents and develop the supplier.

Tracking social audits.

If, during supplier monitoring, certain incidents attributable to the supplier are identified, their qualification status may be modified, potentially leading to disqualification.

Redeia continues working to improve communication and transparency with its suppliers in monitoring and bidding processes. This allows, on the one hand, for a more fluid dialogue and ensures that Redeia’s expectations are known by the supplier, and on the other hand, to develop suppliers, increasing the commitment to generating value for them.